Prestige Termálne meď nikel titánové Hranaté oblúky 10 ks

30.00 € vrátane DPH

Perfektná estetika.

Cu-Alloy wires consists of nickel, titanium and copper. The addition of copper to the alloy enhances the thermal-reactive properties of the wire. The Cu-Alloy wires with the unique thermal-reactive property and mechanics provide a wide range of choice for different cases.

Cu-Alloy is specifically calibrated for use with the ProMIM system and its smooth surface to reduce the sliding friction. Cu-Alloy wires activated temperature is close to mouth temperature and is soft in room temperature to facilitate engagement. It falls within a very efficient force range when used with the large round or rectangle sizes.

Features:

1. Cu-Alloy wires loading forces are smaller then the nickel titanium counterparts

2. Due to the lower hysteresis of Cu-Alloy wires unloading (springback) properties facilitate fast, efficient tooth movement

3. A unique springback characteristic provides continuous forces

4. More resistant to permanent deformation than other nickel-titanium wires

5. Smooth surface to lower down the friction between wires and brackets

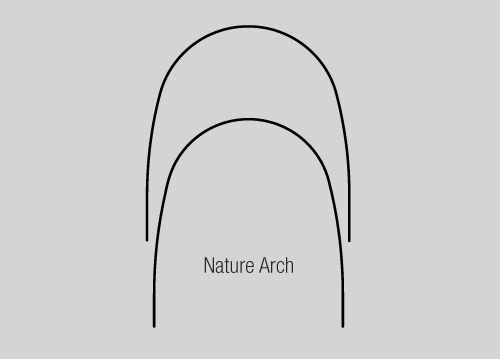

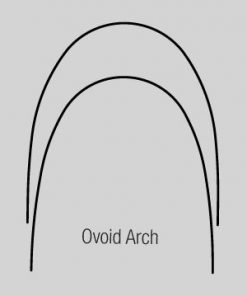

| archform | Horné, Dolné |

|---|---|

| Veľkosť | .016 x .016, .016 x .022, .017 x .022, .017 x .025, .018 x .022, .018 x .025, .019 x .025, .021 x .025 |

Pridajte prvú recenziu pre “Prestige Termálne meď nikel titánové Hranaté oblúky 10 ks” Zrušiť odpoveď

Súvisiace produkty

Meď nikel titánové

Meď nikel titánové

Meď nikel titánové

Recenzie

Nikto zatiaľ nepridal hodnotenie.